Membrane Bio Reactor – MBR

Table of Content

About Membrane Bio Reactors

Traditional Wastewater Treatment vs. Membrane Bioreactor

Benefits of Membrane Bio Reactors

How Membrane Bio Reactors are revolutionizing the Sewage Treatment

Application of MBR Technology

FAQs

———————————————————————————————————————————————————————-

To begin with, wastewater treatment is no longer a luxury. Secondly, it is a necessity that no business can refrain from. Apart from the ability to reuse the water, it has become an important part of compliance and sustainability initiatives.

It was the loop holes in the efficiency of the traditional wastewater management techniques that led to emergence of new technologies. The latest membrane technologies India have witnessed revolution in the form of Membrane Bio Reactor System.

Now, in this blog, we will discuss about what is hollow fiber membrane technology and how they are successfully changing the face of wastewater treatment.

What is Membrane Bio Reactor System – MBR?

A membrane bio reactor is an advanced system designed for wastewater management in an efficient manner. The technique is an amalgamation of biological treatment with membrane filtration.

The conventional methods relied on sedimentation for separation of solid from liquid. However, membrane technology uses semi- permeable membranes. It offers excellent filtration outcome suitable for industrial reuse.

Key Features:

- Removes bacteria, viruses, and suspended solids.

- No need for secondary filtration.

- Highly pure water suitable for industrial usage.

- Lesser risk of operational issues/ system failures.

Components of Membrane Bio Reactor – MBR

- Biological Treatment Unit

- The section acts a traditional activated sludge process.

- Microorganisms breakdown the pollutants and organic matter.

- Oxygen is supplied to enable microbial activity.

- Bacteria degrade the contaminants efficiently.

- Membrane Filtration Unit

- Membrane Bio reactor is the core component.

- Efficient membranes separate treated water from the sludge.

- Membranes are made of Polytetrafluroethylene/ Polyvinylidene fluoride/ Polyethersulfone.

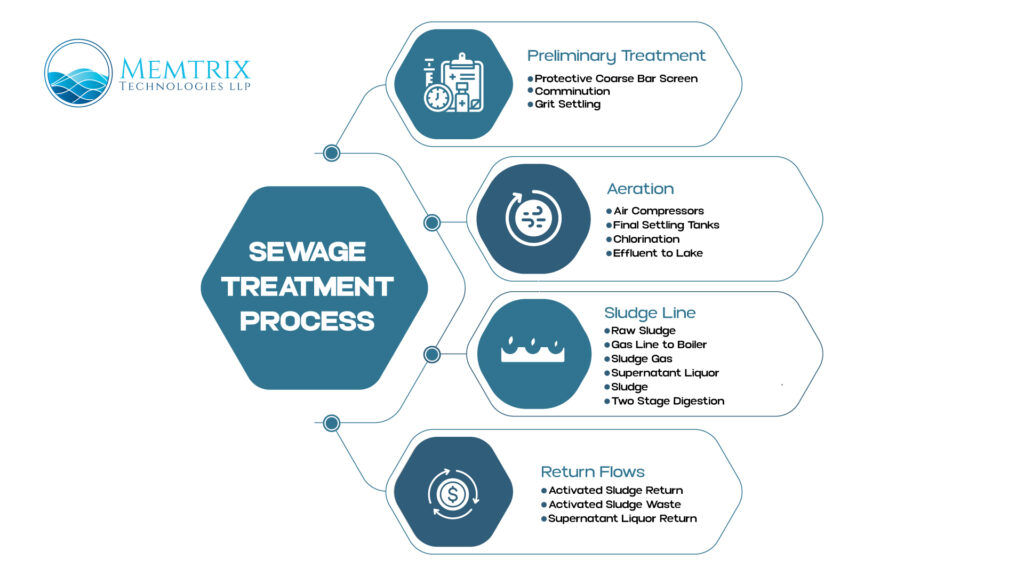

How Does Membrane Bio Reactor – MBR System Work?

Pre- Treatment

Wastewater is processed for removal of sand, grease, and large debris. It is a crucial step to prevent logging the membranes and prolonging their lifespan.

Biological Degradation

Wastewater enters the bioreactor- microorganisms and bacteria breakdown organic pollutants. The aeration system takes care of the oxygen supply. This promotes microbial growth and efficient pollutant removal.

Membrane Filtration

After the biological treatment, the mixture enters the membrane modules. Membranes become the physical barrier and retain pathogens, solids, and bacteria. It allows only clean water through it.

Effluent Reuse

The filtered water received complies with the stringent standards. The water is safe enough to be released into the environment. It is safe to agricultural and industrial use as well.

Traditional Wastewater Treatment vs. Membrane Bioreactor

With increasing demand for clean water due to industrialization and urbanization, the need for latest membrane technologies India became more critical than ever. Among the other available techniques, the membrane bio reactors are gaining momentum rapidly.

MBRs have emerged as superior alternative to the traditional wastewater management systems. Let’s dive deeper into what makes MBRs more efficient, cost-effective, and environment friendly.

About Traditional Wastewater System

Usually, the conventional wastewater treatment system consists of chemical, physical, and biological processes. It’s divided into three stages- primary, secondary, and tertiary.

- Primary Treatment- removes large solids and sediments via screening and settling.

- Secondary Treatment- uses biological process such as activated sludge for degrading the organic matter.

- Tertiary Treatment- consists of nutrient removal, filtration, and disinfection to meet the discharge standards.

Though the conventional systems have been popular for years owing to their effectiveness, they had some limitations. Inconsistent effluent quality, large footprints, and more production of sludge were common limitations. It is here that Membrane technology comes into the picture.

Traditional Vs. Membrane Wastewater Technology

- Effluent Quality

A significant benefit of MBRs over traditional system is the effluent quality. They handle removal of pathogens, contaminants, and suspended solids efficiently as compared to traditional systems. The treated water is suitable for reuse in agriculture and industrial field.

- Space Management

Conventional systems need bigger settling tanks along with different treatment stages. It is spread across a huge area. On the other hand, MBRs are compact. They need lesser space for installation. They are perfect for urban areas with space limitations.

- Sludge Management

MBR filters operate at higher levels of mixed liquor suspended solids concentration. It leads to reduced sludge yield as compared to the traditional methods. It means lesser sludge handling or disposal cost.

- Operational Stability

MBRs offer improved process stability and offers resilience against load fluctuations. The separation process doesn’t depend on gravity settling as they can be affected by variable flow rates. MBRs provide consistent performance with less vulnerability to upsets.

- Cost Consideration

MBR technology leads to higher energy consumption owing to membrane aeration. Though the capital cost is higher, it is cost- effective in the long run. The reduced footprint and water reuse offsets the investment cost.

Benefits of Memtrix Membrane Bio Reactors – MBR

- Quality Effluent

- MBRs offer quality effluent- reduced suspended solids, pathogens, organic matter.

- Small pores of the membranes block the passage of particles.

- MBRs ensure the water meets stringent quality standards.

- Smaller Footprint

- Comparatively MBRs need smaller space for wastewater treatment.

- There is no need for secondary clarifiers.

- MBRs provide compact solution for water filtration.

- They are suitable for areas with space constraint.

- Flexibility and Stability

- The biological treatment in MBRs is stable.

- They are less vulnerable to fluctuations in influent traits.

- Membranes are a barrier to biomass washout.

- They ensure high concentration of microorganisms for water treatment.

- MBRs also handle variations in flow rates and organic loads efficiently.

- They offer flexibility in wastewater treatment.

- Improved Nutrient Removal

- MBRs efficiently remove nitrogen and phosphorous from wastewater.

- Efficient nutrient removal facilitated via extended solids retention time.

- Controlled environment promotes growth of nitrifying and denitrifying bacteria.

Now that we have had a look at the benefits of RPVDF membranes for water treatment, let’s dive deeper into how these membranes are transforming the face of sewage treatment.

How Membrane Bio Reactors are revolutionizing the Sewage Treatment

As mentioned above, the rise in demand for clean water for industrial reuse and sustainable solution, MBRs have emerged as the perfect groundbreaking technology. MBRs are touted as a game- changer in the field of sewage treatment.

The benefits of RPVDF membranes for water treatment increase manifold when biological processes are combined with the membrane filtration.

- Enhanced Efficiency

MBRs are a perfect substitute to the traditional water treatment systems as they are more efficient. The larger surface area for filtration leads to higher biomass concentration.

It leads to thorough nutrient and pollutant removal. It’s compact design and improved hydraulic retention time offers excellent removal of the organic matters.

- Environmental Impact

When sewage water is treated effectively and lesser pollutants are released into the water bodies, it leads to preservation of aquatic ecosystem. Also, this contributes in protection of human health as well.

MBRs produce high quality effluent which is safe to be discharged into the water bodies or sensitive environments.

- Combat Water Scarcity

Scarcity of water is a major concern across the globe and MBRs play a pivotal role in addressing it. They enable reuse of the wastewater for industrial purpose, toilet flushing, and irrigation.

MBRs ensure a stable sustainable water supply and reduce the pressure on fresh water resources.

Application of MBR Technology

Membrane Bio Reactors have several applications. Here’s a look:

- Municipal Wastewater Treatment

- MRBs are extremely popular in the municipal facilities.

- They produce high- quality water and leave smaller footprints.

- MBRs are suitable for upgrading traditional treatment systems.

- Industrial Wastewater Treatment

- Industries release complex and concentrated wastewater.

- It needs advanced treatment for filtration.

- MBRs are a reliable system offering efficient results

- Water Reuse

- MBRs play a crucial role water reuse and application.

- MBR system treats wastewater to be repurposed.

- It’s used for industrial processes, irrigation, and potable water production.

FAQs

- Are MBRs easy to install?

Yes, MBRs don’t need a separate setup. You can easily integrate them with your traditional or existing water treatment setup.

- Which industries can benefit from MBR technology?

- Municipal sewage treatment

- Commercial complexes

- Residential societies

- Industrial effluent management

- Hospitality sector

- Educational institutes

- Are MBRs economically viable for SMEs?

Yes, they are an economically viable solution. Though there is a significant upfront setup cost, in the long-run, MBR proves to be cost- effective.

4.Why are MBRs a game- changer for wastewater management?

High quality effluent, efficient process, and cost- effectiveness offers them an edge. They are redefining the traditional approach towards wastewater.

Conclusion

Memtrix, based in Ahmedabad, India is a leading manufacturer and supplier of MBR. As the technology evolves driven by research and development initiatives, MBR system is becoming more efficient and economically viable.

Memtrix is geared up to offer best solutions with in-house membrane technology, custom design, and domain expertise to every industry. Integration of MBRs with advanced treatments offers a vision of a promising future for sewage water treatment.

Enquire now for your membrane bio reactors which are helpful in wastewater treatment. If you are searching for the best MBR manufacturers, then connect with us now!

Call us or whatsapp us at +91 6355038616

Follow . Share . Like