Membrane systems play a crucial role in industries ranging from wastewater treatment and food processing to pharmaceuticals and desalination. However, one persistent challenge that reduces system efficiency, raises maintenance costs, and shortens equipment life is membrane fouling. Understanding why fouling occurs and how to prevent it through effective membrane fouling solutions is essential for sustainable and cost-efficient operations.

In this guide, we’ll explore the fundamentals of membrane fouling, its major causes, types, and practical solutions to keep your filtration systems performing at their best.

What is Membrane Fouling?

Membrane fouling occurs when unwanted materials accumulate on the surface or within the pores of a membrane, reducing its permeability and flux. In simple terms, fouling clogs the membrane, forcing operators to use more energy and frequent cleaning to maintain system performance.

When left unchecked, membrane fouling can cause:

- Reduced water flow and lower permeate quality

- Increased trans-membrane pressure

- More frequent chemical cleaning cycles

- Shortened membrane lifespan

- Higher overall operational costs

Therefore, early identification and implementation of membrane fouling solutions can mean the difference between a smoothly running filtration system and one plagued by inefficiency.

Common Types of Membrane Fouling

Membrane fouling varies depending on the feed water composition, operating conditions, and membrane material. The major types include:

- Particulate or Colloidal Fouling

This type occurs when suspended solids, silt, or fine particles settle on the membrane surface. These particles create a dense cake layer that restricts flow and increases pressure.

Typical sources: raw water with high turbidity, insufficient pre-filtration, or inadequate sedimentation.

- Organic Fouling

Organic fouling is caused by natural organic matter such as humic acids, oils, fats, and surfactants. These materials adhere strongly to membrane surfaces, reducing permeability and complicating cleaning.

It is common in municipal wastewater, industrial effluent, and food processing applications.

- Biofouling

Biofouling results from microbial growth on the membrane surface. Bacteria attach to the surface and produce extracellular polymeric substances (EPS), forming a sticky biofilm that significantly hampers system efficiency.

This is one of the most complex and persistent fouling types, often requiring a mix of physical and chemical membrane fouling solutions.

- Scaling (Inorganic Fouling)

Scaling occurs when dissolved inorganic salts such as calcium carbonate, calcium sulfate, or silica precipitate and crystallize on the membrane surface. Once formed, these scale layers are difficult to remove and can cause irreversible damage.

Key Causes of Membrane Fouling

Fouling is a multifactorial problem, influenced by several operational and environmental conditions. Understanding these root causes helps in selecting the right prevention strategy:

- Feed Water Quality: High concentration of suspended solids, organic matter, or biological contaminants accelerates fouling.

- Improper Pretreatment: Insufficient filtration, inadequate coagulation, or poor pH control before water enters the membrane system.

- Operating Pressure and Flow Rate: Low crossflow velocity or high pressure can enhance particle deposition on the membrane surface.

- Temperature: Higher temperatures promote biological growth and alter solubility, increasing scaling risks.

- Membrane Material: Some membranes are more prone to adhesion of specific types of foulants based on their surface characteristics.

How Membrane Fouling Impacts System Efficiency

The consequences of membrane fouling go beyond reduced water output. The long-term effects can cripple system economics and sustainability:

- Energy Consumption: As fouling increases resistance, more pressure—and therefore more energy—is needed to maintain desired flux.

- Frequent Downtime: Regular chemical cleaning or membrane replacement interrupts operations.

- Higher Chemical Use: Overuse of cleaning agents adds to environmental load and operational costs.

- Membrane Degradation: Aggressive cleaning can damage the membrane surface, reducing its lifespan.

To combat these challenges, industries implement advanced membrane fouling solutions that combine physical, chemical, and operational controls for lasting results.

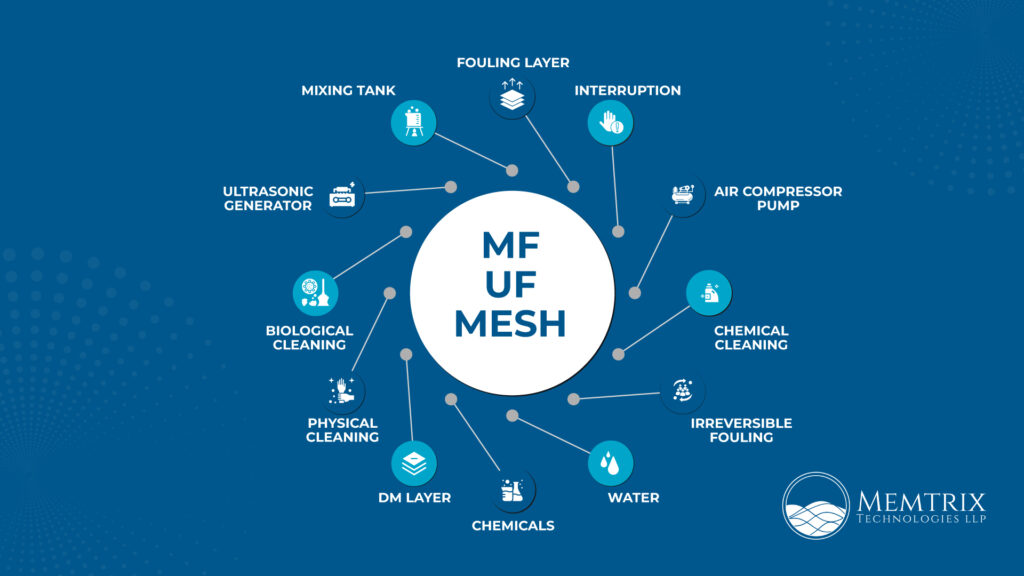

Effective Membrane Fouling Solutions

Managing membrane fouling involves preventive design, optimized operations, and smart cleaning techniques. Below are the most effective strategies implemented in modern membrane systems.

-

Pretreatment Optimization

High-quality pretreatment is the foundation of every effective fouling prevention plan. Depending on water type, this may include:

- Microfiltration or Ultrafiltration: To remove fine particles and organic matter before reverse osmosis (RO) or nanofiltration stages.

- Coagulation and Flocculation: Adding coagulants helps form larger particles that are easier to filter out.

- Activated Carbon Filtration: Effective in removing organic compounds and residual chlorine that can damage membranes.

- pH Control: Maintaining optimal pH minimizes scaling potential.

- Regular Monitoring and Automation

Installing sensors for differential pressure, temperature, pH, and conductivity helps identify early fouling signs. Automated data logging and AI-based predictive maintenance reduce the need for manual intervention and unplanned downtime.

-

Optimizing Operating Conditions

Adjusting flow rates, pressure, and recovery levels helps minimize fouling buildup. A higher crossflow velocity reduces boundary layer thickness and discourages particle deposition.

It is advisable to maintain a stable feed water temperature and avoid drastic changes that can destabilize solubility balances or bio-growth rates.

-

Anti-Fouling Membrane Materials

Modern membranes are designed with surface modifications that repel foulants. Technologies like hydrophilic coatings, surface charge adjustments, or nanocomposite materials improve fouling resistance without compromising permeability.

For example:

- Hydrophilic polymers minimize organic adhesion.

- Positively charged surfaces deter biofilm growth.

- Nanoparticle coatings enhance smoothness, reducing attachment points.

-

Chemical Additives and Antiscalants

Adding antiscalants, dispersants, or biocides to the feed water can significantly slow fouling progression. However, the choice of chemicals must suit both the foulant profile and membrane material.

- Antiscalants control crystal growth and delay scaling.

- Biocides (like chlorine derivatives) control microbial population, though exposure should be limited to chlorine-resistant membranes or neutralized before contact.

- Dispersants prevent aggregation of colloids and organic materials.

-

Scheduled Cleaning and Maintenance

Even with preventive methods, periodic cleaning is inevitable. Successful cleaning programs consider:

- Physical cleaning: forward flushing, backwashing, or air scouring to dislodge particles.

- Chemical cleaning: acidic, alkaline, or enzymatic cleaners formulated for specific foulants.

- Clean-in-place (CIP) systems automate the process for efficiency and consistency.

Maintaining a record of cleaning frequency and performance helps identify patterns for improved control of fouling cycles.

Advanced Technological Approaches

As industries demand higher efficiency, newer analytical and operational technologies are advancing membrane fouling solutions further.

- Electrochemical Cleaning: Uses electrical current to break down biofilms or scale layers without harsh chemicals.

- Ultrasonic Cleaning: Waves disrupt foulant layers mechanically, reducing chemical dependency.

- AI-Powered Monitoring: Machine learning algorithms analyze operational data to forecast fouling trends and optimize backwash scheduling.

- Membrane Surface Engineering: Innovations in nanostructured membranes, polymer grafting, and graphene oxide coatings are pushing fouling resistance to new benchmarks.

These emerging solutions demonstrate how continuous research and technology integration are transforming traditional membrane maintenance approaches.

Best Practices for Long-Term Fouling Control

Ensuring prolonged system health requires combining daily operating discipline with technology-supported monitoring. Here are practical maintenance tips:

- Regularly check differential pressure and flux behavior.

- Maintain accurate dosing of pre-treatment chemicals.

- Avoid sudden shutdowns that can encourage biofilm formation.

- Flush systems with permeate water during idle periods.

- Calibrate sensors and cleaning equipment periodically.

- Train operators on identifying visual and performance-based fouling symptoms.

Such proactive measures build an effective, cost-saving fouling management culture in any membrane-based process.

Membrane fouling is inevitable, but its impact can be dramatically reduced through proper understanding and application of membrane fouling solutions. Every filtration system benefits from a balanced strategy combining improved pretreatment, intelligent process control, chemical optimization, and periodic maintenance.

By addressing fouling before it escalates, industries can extend membrane life, reduce costs, and improve system reliability—ensuring continuous, high-quality output for years to come.

Call us or whatsapp us at +91 6355038616

Follow . Share . Like

Additional Read

What Is a Hollow Fiber Membrane? Working Principle & Key Advantages

MBR vs Conventional Treatment: Why Membrane Systems Are the Future

5 Indications That Your Facility Should Upgrade to Ultrafiltration Membranes