Introduction: The Evolution of Wastewater Treatment

Wastewater treatment has come a long way—from simple settling tanks to advanced integrated systems capable of delivering reusable-quality water. As urbanization accelerates and environmental regulations tighten, industries and municipalities are searching for more sustainable solutions. The debate of MBR vs conventional treatment has thus become central in today’s water management strategies.

The conventional sewage treatment plant (STP) method—based on primary, secondary, and sometimes tertiary stages—has served communities for decades. However, Membrane Bio-Reactor (MBR) technology has begun redefining efficiency standards, compact footprints, and consistent water quality.

Let’s dive deeper into what makes MBR systems the future of wastewater treatment compared to traditional methods.

Understanding Conventional Treatment Systems

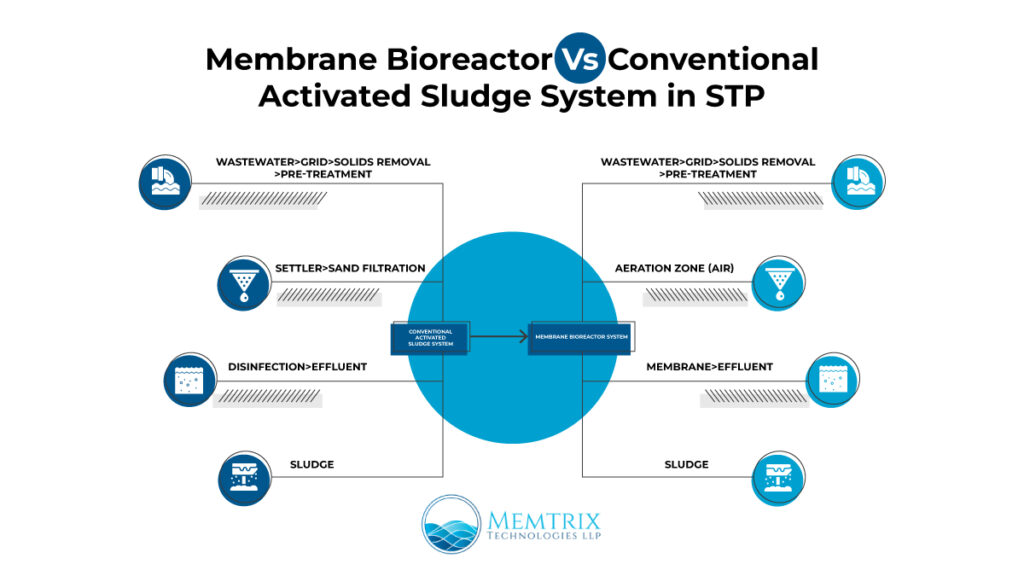

Traditional wastewater treatment works through a sequence of steps designed to separate and reduce contaminants before discharge or reuse. A typical STP includes:

- Primary Treatment: Physical separation of solids through screening and sedimentation.

- Secondary Treatment: Biological degradation using aerobic or anaerobic microbes to break down organic matter.

- Tertiary Treatment (optional): Further chemical or filtration processes for polishing the water quality.

While effective, conventional systems rely heavily on gravity-based settling and biological oxidation, leading to large space requirements and variable performance. The treated water may still contain suspended solids, pathogens, and nutrients that limit reuse potential.

Key challenges associated with conventional STPs include:

- High land area consumption.

- Odor generation due to open aeration tanks.

- Inconsistent treated water quality.

- Frequent sludge handling requirements.

- Limited scope for direct reuse in industrial or irrigation applications.

These challenges have paved the way for compact and smarter solutions—led by MBR technology.

What Is MBR? How Does It Work?

MBR (Membrane Bio-Reactor) combines biological treatment and membrane filtration in a single integrated system. Instead of relying on gravity to separate solids (like conventional systems), MBR uses microfiltration or ultrafiltration membranes to physically retain all suspended solids, bacteria, and pathogens.

The process typically includes:

- Biological reactor: Organic matter is degraded by microorganisms under controlled conditions.

- Membrane filtration unit: The treated water passes through semi-permeable membranes, leaving solids behind and producing crystal-clear effluent.

The result? A highly efficient system producing water clean enough for reuse in gardening, flushing, cooling towers, and other non-potable applications.

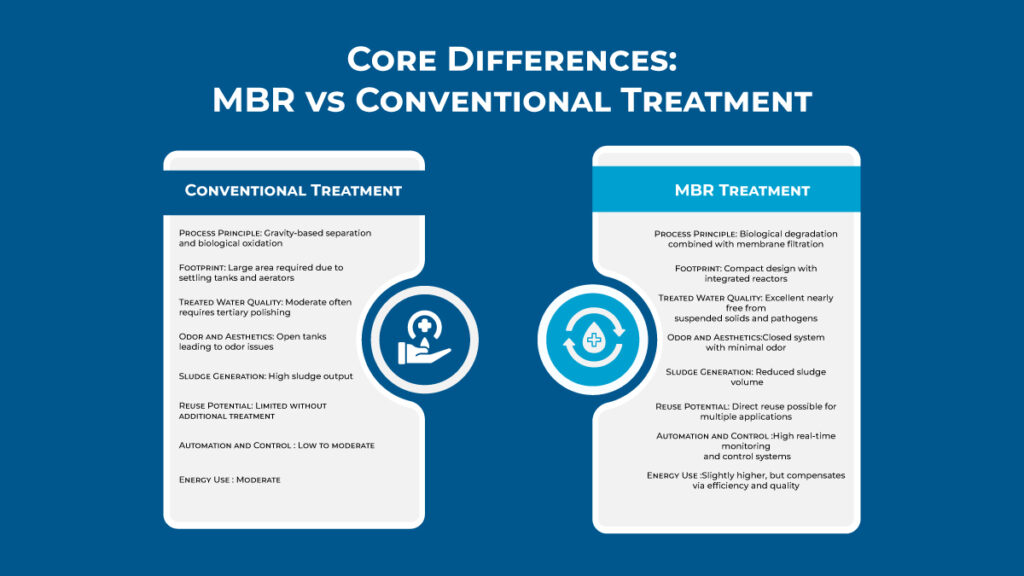

Core Differences: MBR vs Conventional Treatment

| Aspect | Conventional Treatment | MBR Treatment |

| Process Principle | Gravity-based separation and biological oxidation | Biological degradation combined with membrane filtration |

| Footprint | Large area required due to settling tanks and aerators | Compact design with integrated reactors |

| Treated Water Quality | Moderate—often requires tertiary polishing | Excellent—nearly free from suspended solids and pathogens |

| Odor and Aesthetics | Open tanks leading to odor issues | Closed system with minimal odor |

| Sludge Generation | High sludge output | Reduced sludge volume |

| Reuse Potential | Limited without additional treatment | Direct reuse possible for multiple applications |

| Automation and Control | Low to moderate | High—real-time monitoring and control systems |

| Energy Use | Moderate | Slightly higher, but compensates via efficiency and quality |

Why MBR Systems Are Transforming Wastewater Reuse

- Superior Effluent Quality

One of the defining advantages of MBR systems is the unmatched effluent clarity. The membranes act as a physical barrier, removing suspended solids and microorganisms down to 0.01 microns. This results in consistent, high-quality water suitable for reuse or discharge into sensitive environments.

- Compact Design and Space Efficiency

Compared to conventional treatment, MBR systems require up to 60% less space. The absence of secondary sedimentation tanks and tertiary filtration units makes MBR ideal for urban sites where land cost is high.

- Enhanced Process Stability

MBR technology maintains stable biological activity even with variable influent loads. Conventional systems often falter with shock loads or flow fluctuations. MBR’s controlled environment ensures better adaptability and consistent performance year-round.

- Simplified Operations and Automation

Modern membrane systems integrate IoT and SCADA-based automation for real-time monitoring of DO, flux rates, and membrane health. Automated backwashing cycles and cleaning protocols minimize manual intervention, reducing operational errors and labor requirements.

- Efficient Sludge Management

MBR systems inherently reduce sludge generation due to extended sludge retention time (SRT). Lower sludge volumes mean fewer disposal cycles, translating to reduced operating costs and environmental burden.

Comparing Long-Term Costs and ROI

From a capital expenditure (CAPEX) standpoint, MBR systems may seem pricier due to membrane modules and control instrumentation. However, lifecycle performance tells a different story:

- Reduced footprint saves land acquisition costs.

- Lower sludge disposal expenses accumulate crucial savings.

- Superior water reuse potential diminishes the need for fresh water.

- Minimal operator intervention lowers staffing expenses.

Over a 10-year horizon, MBR systems often prove 25–40% more cost-effective than conventional treatment setups when considering total cost of ownership (TCO).

Environmental and Regulatory Benefits

Global and national wastewater discharge norms are becoming stricter—especially regarding Biological Oxygen Demand (BOD), Chemical Oxygen Demand (COD), Total Suspended Solids (TSS), and microbial counts.

MBR systems can easily meet and exceed the highest discharge standards:

- BOD < 5 mg/L

- TSS < 1 mg/L

- Pathogen removal up to 99.9%

Compliance with these standards not only ensures regulatory safety but also improves corporate sustainability credentials. Many industries—including pharmaceuticals, textiles, and food processing—are adopting MBRs to achieve “Zero Liquid Discharge (ZLD)” or water reuse certification.

MBR in Industrial and Municipal Applications

MBR technology is now applied in a wide range of sectors:

- Municipal wastewater treatment plants: Compact and odor-free operation within cities.

- Hospitals and hotels: Producing hygienic water for flushing and gardening.

- Industries: Reusing water in cooling towers or process lines.

- Housing projects: Meeting green building and water reuse requirements.

In India and globally, several smart-city projects now incorporate decentralized MBR-based STPs for sustainable water management.

Technological Innovations Driving MBR Adoption

Recent developments have addressed key limitations that once hindered MBR growth:

- Advanced membrane materials with anti-fouling coatings.

- Energy-efficient blowers and aeration systems.

- Smart membrane cleaning cycles improving lifespan.

- Hybrid MBR designs combining MBBR + MBR for enhanced performance.

These innovations have significantly reduced the maintenance overheads and power consumption of MBRs—making them an attractive alternative to outdated STPs.

Sustainability Perspective: Recycling Every Drop

The global push for water conservation demands systems that not only treat wastewater but also make it reusable. MBR emerges as a leading contender for circular water management.

Conventional STPs focus on discharge compliance, whereas MBR goes beyond to enable resource recovery and reuse. Recyclable water from MBRs contributes to reducing groundwater extraction and cuts dependence on municipal supply—a win-win for industries and urban communities alike.

Moreover, closed operational designs ensure lower carbon footprint, minimal odor emissions, and better hygiene compared to traditional open-aeration plants.

Future Outlook: MBR as the Global Standard

With governments and urban planners embracing sustainable infrastructure, Membrane Bio-Reactor systems are positioned to become the global standard. The combination of compact engineering, reliability, and water reuse potential aligns perfectly with next-generation water management policies.

In fact, smart infrastructure guidelines increasingly recommend MBR-based STPs for residential, commercial, and industrial developments, especially in water-scarce regions.

The next decade will likely witness:

- Widespread adoption of decentralized MBR units.

- Integration with IoT-based water quality monitoring.

- Decline of conventional STP models relying solely on gravity separation.

Conclusion: Choosing the Future with MBR

As the debate of MBR vs conventional treatment continues, facts remain clear—MBR systems provide better performance, higher water quality, and lower environmental impact.

For any builder, municipality, or industrial operator planning a wastewater upgrade, transitioning to Membrane Bio-Reactor technology isn’t just a technical choice; it’s a strategic decision aligned with the future of sustainability.

The world is moving toward smarter, cleaner, and space-efficient treatment solutions—and Memtrix technology’s MBR stands at the forefront of that revolution.

Enquire now for your MBR systems which are helpful in wastewater treatment. If you are searching for the best MBR manufacturers, then connect with us now!

Call us or whatsapp us at +91 6355038616