In This Blog: Key Topics Covered on RPVDF Membranes for Water Treatment

- About hollow fiber membrane technology

- Characteristics of hollow fiber membranes

- About RPVDF membranes- types and its benefits

- Latest membrane technologies in India

- FAQs

Hollow fiber membranes play a significant role in medical and industrial fields. They are used for different filtration and purification processes. These membranes are widely used for their efficiency and technology. Effective removal of contaminants and dissolved substances is important in reverse osmosis and ultrafiltration.

Let’s take a detailed look at what is hollow fiber membrane technology.

Everything You Need to Know About Hollow Fiber Membrane Technology

Hollow fiber filtration is like a semi- permeable membrane. It is like a tube with less than a millimeter diameter. It works on the similar concept of capillary configuration. However, it uses small tube diameter allowing flexibility.

- It contains thousands of porous, long filaments.

- The filaments are potted together in a PVC shell.

- Each filament ranges from 1 to 3.5 mm.

- They are flexible with narrow diameter.

- Common applications- reverse osmosis and microfiltration.

These filaments resembling tiny straws are bundled for creating the filter matrix. The walls of the tubes contain holes/ microscopic pores. When you pump the water through the pump, contaminants and microbiological threats get trapped inside.

This filtration method is also known as size exclusion. The pores are too small in size, simply microscopic. They allow the smaller molecules i.e. water to pass and retains the contaminants.

Characteristics

- Bundling small fibers creates a substantial membrane surface in a small volume, increasing the filtration capacity.

- Hollow fiber membranes need lesser space than flat- sheet membranes.

- Fibers offer their own mechanical support. It simplifies design and use.

- These membranes have diverse applications in various industries.

- It is easy to clean and maintain in the long- run.

Now, that we have had a look at what is hollow fiber membrane technology, it’s time to dig a little deeper into the types of membranes and its applications.

How Can RPVDF Technology Membrane for Water Treatment Benefit

RPVDF- Reinforced Polyvinylidene Fluoride is a type of hollow fiber membrane. Particularly, it is used in different types of separation and filtration processes. In addition, water management, wastewater treatment, and gas separation are also some of the major processes that use RPVDF technology.

These membranes are made of PVDF polymer. However, it is durable and chemical resistant with added reinforcement. This leads to enhanced strength. So, let’s dive deeper into how RPVDF works:

- PVDF is a popular choice for membrane production.

- It offers thermal stability, chemical resistance, and mechanical strength.

- PVDF has hydrophobic properties and offers resistance to fouling.

- PVDF is efficient in filtration of gases and liquids.

About Reinforcement Technology

The technology adds to the existing benefits of PVDF membranes. It improves the structural integrity and mechanical strength of the PVDF membranes. Reinforcement technique is deployed in the manufacturing process itself.

The technique works by adding the desired structure and material into the membrane matrix. It enhances the durability of the hollow fiber membranes.

Types of Reinforcements

Here’s a look at some benefits of RPVDF membranes for water treatment:

There are different methods used for reinforcing strength in the PVDF membranes.

- Inorganic Fillers- Alumina, Silica, Titanium Dioxide Nanoparticles

- These fillers when reinforced into the PVDF matrix.

- They increase the tensile strength and resistance to any physical stress.

- Polymeric Additives- Polyethylene, Polypropylene, Polysulfone

- These fillers add to the mechanical properties of the hollow fiber membrane.

- They improve resistance to damage and deformation, and tensile strength.

- Mesh/ Fabric Reinforcements- Polyester, Polyamide

- These reinforcements are wrapped around the PVDF membranes.

- They offer structural support and strength to the membranes.

- They prevent collapse of the fibers and resistance to pressure.

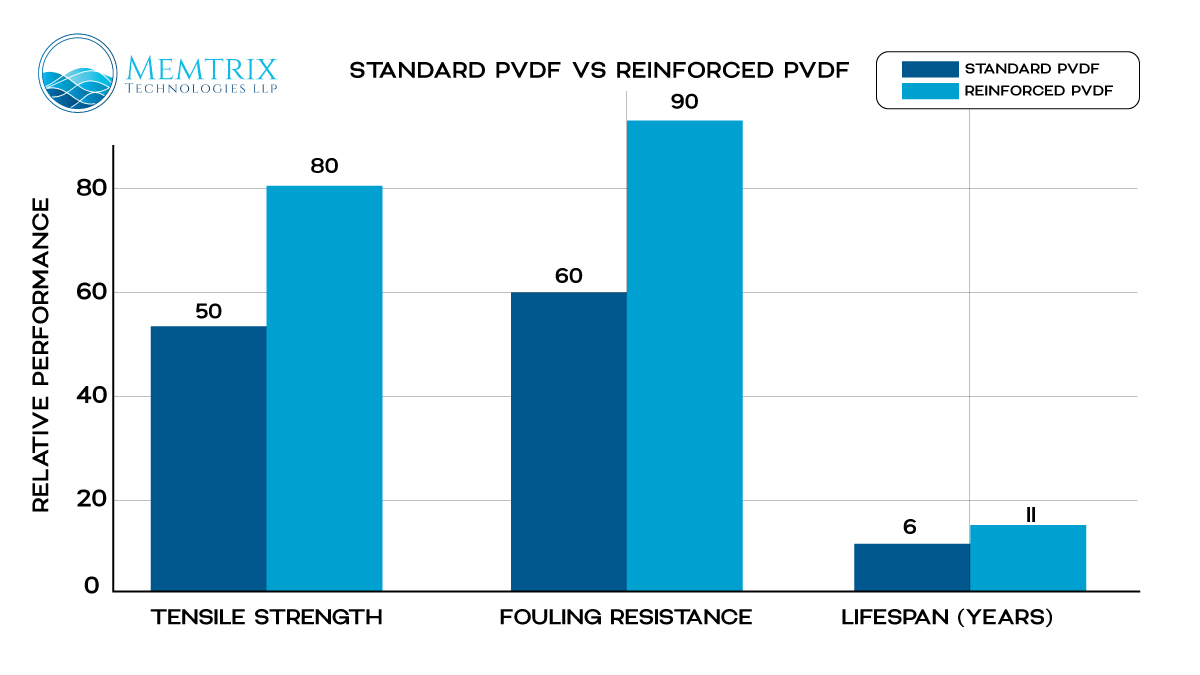

Advantages of Reinforced PVDF Hollow Fiber Membranes

Some benefits of RPVDF membranes for water treatment are as follows:

1.Improved Mechanical Strength

Reinforcement drastically improves the mechanical strength of the membranes. This makes them resistance to physical stresses such as cyclic loading or pressure. Also, it helps the hollow membranes to sustain the high operating pressure. It prolongs the lifespan of the membranes significantly.

2.Improved Thermal and Chemical Resistance

PVDF in itself displays solid thermal and chemical resistance. Then, with reinforcement added to the membrane, it becomes stronger. The PVDF becomes sturdy enough to sustain high temperatures, fouling agents, and harsh chemicals.

They can withstand challenging and aggressive surroundings. The sturdiness makes them suitable for diverse applications across industries.

3.Prevents Membrane Fouling

When PDVF membranes are reinforced, they possess hydrophobic properties and improved strength. Additionally, this makes them less prone to fouling. Their surface becomes smoother and resistant to adhesion.

It prevents particles, organic matters and any biological growth from getting accumulated. Cleaning and maintenance becomes easier with longer intervals.

4.Higher Filtration Efficiency

PVDF hollow fiber membranes offer high filtration efficiency, even without reinforcement. This is owing to the small pore size and amazing sieving properties.

Furthermore, the membranes can efficiently separate the colloidal particles, suspended solids, microorganisms, and dissolved particles. It leads to high- quality filtration results.

Also, reinforcement process plays a crucial role in enhancing the efficiency of the PVDF hollow fiber membranes.

- Reinforcement is a robust and reliable solution for different filtration processes.

- Chemical resistance, mechanical strength, and excellent filtration properties are the key advantages.

- Reinforcement makes PVDF membranes suitable for gas separation, wastewater management, and industrial filtration.

- The choice of reinforcement technique varies depending on the application.

- The operating condition of the membrane system also decides the type of reinforcement.

Explore Latest Membrane Technologies in India

If you are looking for latest membrane technologies India, Memtrix Technologies LLP offers the perfect solution. Specialising in the smart membrane technology, they are at the forefront of transforming the filtration technology.

With rise in the demand for wastewater management, hollow fiber membranes are not just a technology- they are a necessity. Based in Ahmedabad, India, Memtrix designs and manufactures cutting- edge membranes for diverse industrial usage.

They enable businesses from diverse industries to conserve and reuse water sustainably. With their latest membrane technologies India, Memtrix is creating an environment where water is not waster but used wisely.

FAQs

1. Are all hollow fiber membranes same?

No, all hollow fiber membranes are not the same; they differ in quality as well as durability, ability, and flow rate. Always buy from a reputed manufacturer such as

2.Is there a specific role of water filter pore size?

To begin with, pore size signifies the size of microbes it is designed to remove. For instance, a microfilter should have pore size of 0.2 microns. This enables it to remove all bacteria and protozoa.

3. What are the tips to care for hollow fiber membrane?

The hollow fiber technology is delicate and requires some care for longevity.

- Avoid dropping the hollow fiber filter.

- Store in a dry place and avoid freezing.

- It is important to regularly backflush the filter.

Reviews

- Our journey with water filtration systems has been relatively new. And, we are glad to have partnered with Memtrix. With their efficient and effective RPDVF system, we have been able to reuse water which is a step towards sustainability. It makes for a cost-effective solution as well!

- Having worked with different water filtration solutions in the past decade, we were looking for a better solution. And with Memtrix, we found the best! With efficient water filtration results and lesser maintenance needs, it has proved to be a cost- effective solution for a small scale business like ours.

- Memtrix hollow fiber membrane filtration system is by far one of the most reliable and efficient one. We have witnessed excellent results in the form of desired performance thereby reducing the operational cost. And, it is a sustainable solution- best for conservation of the planet.

Enquire now for your RPVDF membranes for water treatment. If you are searching for the best hollow fiber membranes, then connect with us now!

Call us or whatsapp us at +91 6355038616

Follow . Share . Like