Introduction

Indications

- Ineffective Filtration Performance

- Increased Operational Costs

- Inability to Achieve Water Quality Standards

- Rising Demand for Clean Water

- Increased Environmental Concerns

FAQs

Conclusion & Citations

————————————————————————————————————————————————————————-

Clean water or air is slowly becoming luxuries for everyone. And when it comes to have clear water, UF or Ultra Filtration is something that comes to mind.

Ultrafiltration (UF) membranes manufactured by Memtrix Technologies are changing the water treatment landscape in industrial, commercial and residential facilities. As growing needs for clean, efficient, and sustainable water processing have become more prominent, ultrafiltration has become a leading and cutting- edge technology. If your facility is experiencing clogged old filtration systems, it may be time to upgrade to UF membranes made by Memtrix Technologies.

Here are five indications that it’s time to make the upgrade: These advanced systems offer superior removal of contaminants, ensuring higher water quality and operational reliability compared to conventional methods (Ghonimy et al., 2025).

Ineffective Filtration Performance

Poor filtration performance is one of the most prevalent indicators that your current filtration system requires an upgrade. If your plant is dealing with recurrent clogging, reduced filtration rates, or variable water quality, it’s an unmistakable sign that the existing system is no longer functioning at its best.

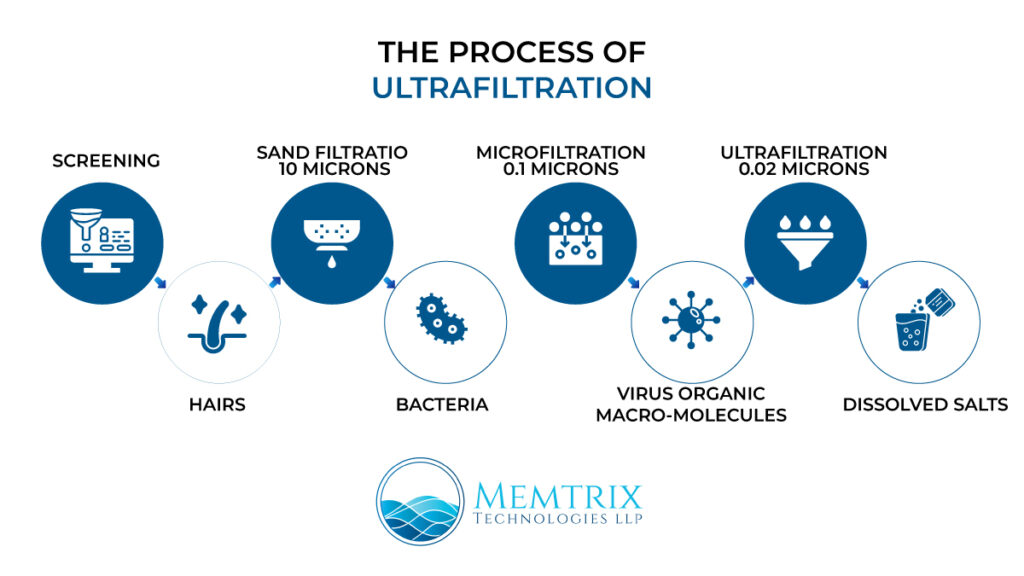

Ultrafiltration membranes offer significantly improved filtration with high flow rates and predictable outcomes. Unlike conventional filtration techniques, UF membranes can effectively filter suspended solids, bacteria, viruses, and colloidal particles as small as 0.02 microns. This precise filtration capability makes them a preferred choice for industrial applications such as pharmaceuticals, food processing, and water treatment, where stringent purity standards are crucial.

Beyond their superior filtration, ultrafiltration systems are also more efficient and long-lasting than outdated mechanisms like reverse osmosis or microfiltration. If your existing system struggles to meet the growing demand for pure water or support greater load capacities, then it’s time to seek a stronger solution from an industrial ultrafiltration systems manufacturer in India like Memtrix Technologies LLP or a membrane bioreactor solutions provider. Moreover, UF systems often exhibit lower energy consumption compared to reverse osmosis, making them a more sustainable choice for high-volume water treatment (Aziz et al., 2024).

Increased Operational Costs

Older filtration devices often lead to higher operational costs due to their need for extensive maintenance and chemical usage. In contrast, UF membranes require fewer chemicals, significantly reducing overall expenses. Their stable performance and long lifespan also translate into fewer maintenance interventions and less downtime.

Furthermore, back washing and cleaning operations with UF membranes are generally less energy-intensive, leading to long-term energy savings. By upgrading to ultrafiltration, your plant can achieve not only enhanced efficiency but also significant cost savings. Companies, such as hollow fiber membrane sellers in Ahmedabad, can provide solutions to help minimize these operational overheads. This transition can also lead to a reduction in waste production and chemical consumption, further contributing to environmental sustainability goals (Touffet et al., 2015).

Inability to Achieve Water Quality Standards

For critical industries like pharmaceuticals, food and beverage, and electronics production, maintaining high water quality standards is non-negotiable. If your current filtration system fails to consistently deliver the required water quality, it’s a clear indication that an upgrade is essential.

Ultrafiltration systems produce high-quality filtrates, effectively removing contaminants such as heavy metals, microorganisms, and colloidal particles that conventional filters often miss. This ensures your water consistently meets stringent production requirements. Furthermore, UF membranes require less extensive pre-treatment and reliably provide a clean output that adheres to all regulatory standards. This capability is particularly vital in mitigating the impact of industrial and urban effluents that introduce a wide array of pollutants, including pharmaceuticals, dyes, and pesticides, into water sources (Asghar et al., 2024).

Rising Demand for Clean Water

As businesses expand and regulatory requirements become stricter, the need for purified water grows. If your existing system cannot supply the necessary quantity of water or properly treat water from various sources, it’s time to consider an upgrade.

Ultrafiltration membranes are highly scalable, making them easy to integrate into systems facing increasing water demands. Whether your facility needs expanded filtration capabilities or reduced water wastage, UF membranes offer the versatility and dependability to accommodate both. With membrane bioreactor technology solutions, UF systems can effectively treat wastewater, enabling water recycling within your facility and decreasing reliance on external water supplies. This enhanced capacity for water reuse not only bolsters operational resilience but also aligns with corporate sustainability objectives, offering a strategic advantage in resource management. Moreover, by reducing the reliance on external water sources, facilities can also mitigate risks associated with water scarcity and fluctuating supply costs, thereby enhancing long-term operational stability.

Increased Environmental Concerns

Environmental sustainability is a growing concern for companies globally. Ultrafiltration membranes offer a solution by providing cost-effective and environmentally friendly filtration systems. These membranes contribute to sustainability by having lower carbon emissions and producing less waste compared to traditional filtration methods.

Furthermore, UF membranes are less energy-intensive and require fewer chemicals for cleaning, thereby reducing your facility’s environmental footprint. As industries face increasing pressure to adopt greener technologies, transitioning to ultrafiltration membranes can significantly enhance your facility’s green credentials. As a supplier of hollow fiber membranes in Ahmedabad, you can be confident that your facility is implementing one of the most environmentally sound filtration options available on the market. Additionally, the robust nature of UF membranes, often made from polymers like polysulfone or polyethersulfone, ensures extended operational lifespans, further contributing to reduced waste and resource consumption (Aziz et al., 2024).

FAQs

What is Ultra Filtration (UF) Membrane – Memtrix Technologies?

Ultra filtration (UF) membrane is a physical filter with very tiny pores that helps in separating any kind of substances from water. All the solutes and solids are retained due to their weight and water passes through these membranes making the process of filtration better and efficient.

Why to go for Ultra filtration water treatment process?

The first and foremost reason to go for a UF water treatment process is that it helps in removing impurities as small as 0.01 microns. Also, it can be automated without any kind of operator dependency.

What contaminants can UF membranes remove?

UF – memtrix technologies can remove the following contaminants:

- Sediments

- Rust

- Bacteria and most of the viruses

- Suspended solids

- Large organic molecules

- Pesticides

- Fats and proteins

What cannot be removed by the UF membranes?

- Dissolved salt

- Dissolved minerals

- Heavy metals

Conclusion and Citations

Upgrading to ultrafiltration membranes can revolutionize your plant’s operations. Whether your facility is struggling with inefficient filtration performance, rising operational costs, or increasing environmental concerns, UF membranes offer a viable and comprehensive solution.

By investing in ultrafiltration technology, your plant can not only meet the growing demand for purified water but also establish a foundation for a greener, more efficient future. If you are planning an upgrade, collaborating with an industrial ultrafiltration systems manufacturer in India or a membrane bioreactor solutions company will help you identify the most effective solutions tailored to your facility’s needs. For water treatment, wastewater recycling, or process filtration, ultrafiltration stands as a future-proof solution, delivering efficiency, cost-effectiveness, and sustainability.

Recognizing these five signs empowers you to make an informed decision to upgrade your filtration system and stay ahead of industry trends. This proactive approach ensures optimal performance and adherence to increasingly stringent environmental regulations. Such upgrades are critical for ensuring long-term operational viability and achieving superior water quality outcomes across diverse industrial applications (Christensen & Gilabert-Oriol, 2023) (Asghar et al., 2024).

Asghar, N., Hussain, A., Nguyễn, Đ. A., Ali, S., Hussain, I., Junejo, A., & Ali, A. (2024). Advancement in nanomaterials for environmental pollutants remediation: a systematic review on bibliometrics analysis, material types, synthesis pathways, and related mechanisms [Review of Advancement in nanomaterials for environmental pollutants remediation: a systematic review on bibliometrics analysis, material types, synthesis pathways, and related mechanisms]. Journal of Nanobiotechnology, 22(1). BioMed Central. https://doi.org/10.1186/s12951-023-02151-3

- Aziz, S., Mazhar, A. R., Ubaid, A., Shah, S. M. H., Riaz, Y., Talha, T., & Jung, D. W. (2024). A comprehensive review of membrane-based water filtration techniques [Review of A comprehensive review of membrane-based water filtration techniques]. Applied Water Science, 14(8). Springer Nature.

- Christensen, M. L., & Gilabert-Oriol, G. (2023). Microfiltration and ultrafiltration. In IWA Publishing eBooks (p. 27). UWA Publishing. https://doi.org/10.2166/9781789062977_0027

- Ghonimy, M., Alharbi, A., Saad, S., & Hussein, N. (2025). Improving Wastewater Quality Using Ultrafiltration Technology for Sustainable Irrigation Reuse. Water, 17(6), 870.

- Touffet, A., Barón, J., Welté, B., Joyeux, M., Teychené, B., & Gallard, H. (2015). Impact of pretreatment conditions and chemical ageing on ultrafiltration membrane performances. Diagnostic of a coagulation/adsorption/filtration process. Journal of Membrane Science, 489, 284. https://doi.org/10.1016/j.memsci.2015.04.043

Enquire now for your ultrafiltration membrane which are helpful in wastewater treatment. If you are searching for the best MBR manufacturers, then connect with us now!

Call us or whatsapp us at +91 6355038616

Follow . Share . Like